Typical Problems Fixed by Commercial Refrigerator Repair Professionals in Toronto

Typical Problems Fixed by Commercial Refrigerator Repair Professionals in Toronto

Blog Article

Troubleshooting Business Refrigeration Repair Work: Strategies for Quick and Effective Fixes

In the realm of industrial refrigeration, the requirement for swift and precise troubleshooting methods is critical. When a refrigeration unit breakdowns, the consequences can be turbulent and costly to business procedures. Comprehending the typical issues that plague business refrigeration systems and having a toolkit of analysis techniques available can make all the distinction in swiftly identifying and correcting troubles. As we browse with the complexities of repairing industrial refrigeration repair service, we will reveal the vital approaches for solving problems effectively, making certain that companies can keep optimal cooling efficiency and decrease downtime.

Common Commercial Refrigeration Problems

Business refrigeration systems generally encounter a series of functional concerns that can interrupt their efficiency and efficiency. One widespread concern is improper temperature control, which can bring about food putridity and waste otherwise without delay addressed. This issue may stem from issues with the thermostat, evaporator fan, or condenser coils, calling for comprehensive assessment to pinpoint the source. Another usual concern is poor air flow, typically caused by clogs in the vents or a malfunctioning follower. Poor air flow can bring about temperature inconsistencies within the refrigerator or fridge freezer, affecting the quality and safety and security of stored items.

Furthermore, refrigerant leaks posture a significant problem as they not only affect the air conditioning capacity of the system however also contribute to environmental damage. Regular cleaning and maintenance can aid stop this issue and extend the life-span of the refrigeration system.

Diagnostic Tools and Strategies

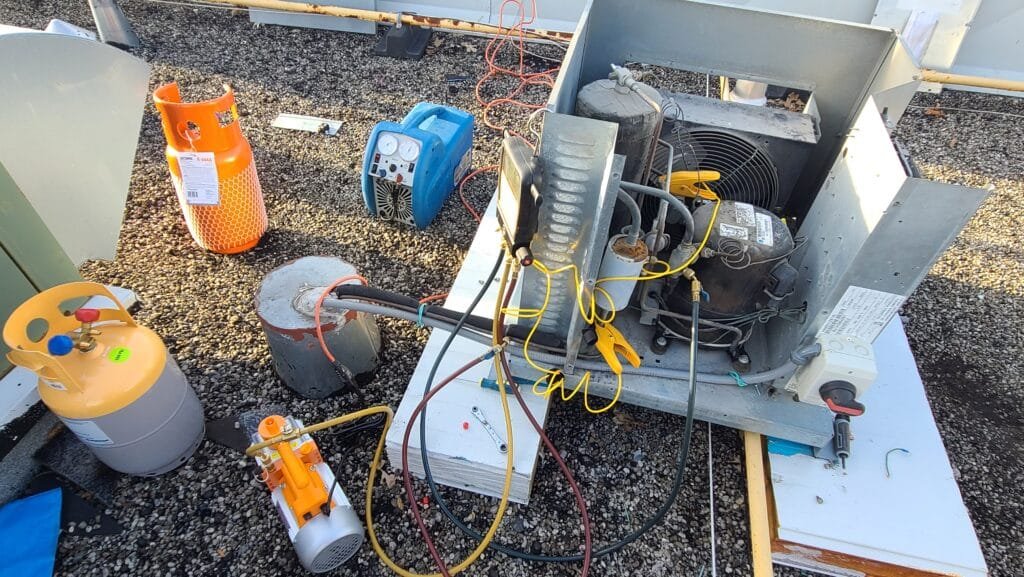

Reliable troubleshooting of business refrigeration systems relies heavily on utilizing specialized diagnostic devices and strategies to recognize and settle underlying concerns successfully - Toronto commercial refrigerator repair. In addition, leakage detection tools like electronic leakage detectors or ultraviolet color sets are important for finding refrigerant leakages that can lead to system inefficiencies.

Strategies such as pressure testing using manifold determines can establish if the system has the right cooling agent charge and identify any kind of leaks. Visual inspections of components for indications of wear, rust, or ice build-up are also basic in identifying concerns. Additionally, information loggers can be utilized to monitor system performance with time and find trends that might indicate recurring troubles. By combining these diagnostic devices and techniques, service technicians can efficiently fix business refrigeration systems and offer fast and precise repair work, minimizing downtime and making certain optimal system performance.

Quick Solutions for Refrigeration Issues

When encountered with refrigeration issues, service technicians can carry out quick fixes to resolve typical issues quickly and efficiently. If the refrigeration device is not cooling down correctly, checking and readjusting the thermostat settings might supply a quick service prior to even more extensive troubleshooting is required. By applying these quick solutions, service technicians can deal with common refrigeration troubles efficiently and maintain industrial refrigeration systems running efficiently.

Preventative Upkeep Tips

Implementing an aggressive maintenance timetable is critical for making sure the longevity and optimum efficiency of commercial refrigeration systems. Regular maintenance not just assists prevent pricey breakdowns yet likewise ensures that the devices runs successfully, saving power and reducing general operating prices. Right here are some preventative upkeep suggestions to maintain industrial refrigeration systems running smoothly:

Inspect and Replace Filters: Filthy filters can limit air sites flow, making the system work tougher and potentially causing damage. Inspect and replace filters consistently to stop issues.

Inspect Seals and Gaskets: Leaking seals and gaskets can cause temperature variations and energy wastefulness. Checking and replacing damaged seals can assist keep constant temperature levels.

Specialist Support and Provider

To preserve the optimal efficiency accomplished through normal preventative maintenance, looking for expert support and solutions for industrial refrigeration systems is important. look at this now Specialist professionals possess the competence and specialized knowledge called for to diagnose and resolve complicated concerns effectively. When facing tough refrigeration problems, counting on professional assistance can conserve both time and money over time.

Professional services supply advantages such as accessibility to advanced devices and equipment, making sure that repair work are executed efficiently. In addition, professionals are trained to stick to sector policies and safety and security standards, minimizing the risk of mishaps and ensuring compliance with lawful demands.

Final Thought

Finally, repairing industrial refrigeration fixing needs an organized technique to recognizing typical issues, making use of diagnostic tools and strategies, executing fast fixes, and prioritizing preventative upkeep. Professional support and solutions may be essential for even more facility problems - commercial refrigeration repair. By complying with these approaches, companies can guarantee their refrigeration systems operate successfully and effectively, reducing downtime and prospective losses

Recognizing the typical concerns that plague commercial refrigeration systems and having a toolkit of diagnostic techniques at your disposal can make all the distinction in swiftly determining and treating issues.Reliable troubleshooting of industrial refrigeration systems counts heavily on utilizing specialized analysis tools and techniques to determine and resolve underlying problems effectively. By incorporating these diagnostic tools and strategies, service technicians can efficiently repair business refrigeration systems and provide quick and precise repair services, minimizing downtime and making certain optimal system efficiency.

By applying these fast solutions, technicians can deal with common refrigeration problems successfully and maintain industrial refrigeration systems running smoothly.

Moreover, specialist assistance can assist expand the lifespan of industrial refrigeration systems by identifying potential concerns prior to they escalate.

Report this page